Help

VAMS Mechatronica Private Limited

An Industrial Automation Solutions Company

How are we connecting to PLC ?

At VAMS Mechatronica, our application ensures seamless connectivity to Programmable Logic Controllers (PLCs) through a robust integration of OPC UA, TCP/IP, and MQTT protocols. This multi-faceted approach provides flexibility, reliability, and efficiency in industrial automation systems.

OPC UA (Open Platform Communications Unified Architecture):

OPC UA is an industrial communication protocol that ensures secure and reliable data exchange between our application and PLCs. It offers platform independence, high scalability, and robust security features, making it ideal for diverse industrial environments.

TCP/IP (Transmission Control Protocol/Internet Protocol):

TCP/IP is the fundamental suite of communication protocols used for interconnecting network devices on the internet. By utilizing TCP/IP, our application achieves direct and efficient communication with PLCs, ensuring fast and reliable data transfer.

MQTT (Message Queuing Telemetry Transport):

MQTT is a lightweight messaging protocol designed for low-bandwidth, high-latency, or unreliable networks. Its publish/subscribe model enables efficient and real-time data exchange between our application and PLCs, enhancing responsiveness and performance in monitoring and control tasks.

By leveraging these advanced communication protocols, VAMS Mechatronica's application guarantees robust connectivity, real-time data access, and enhanced operational efficiency for your industrial automation needs.

What are the requirements to connect Siemens PLC?

Requirements:

CPU Version:

SIMATIC S7-1500 - V2.5 or later

SIMATIC S7-1200 - V2.5 or later

ET 200MP

ET 200SP

ET 200AL

ET 200pro

TIA Portal:

Version 14.0 or later

For standardized, communication of an S7 control system that applies to all platforms and manufacturers, Siemens offers you the communication protocol OPC UA. As of firmware version V2.5 and TIA Portal V15, the SIMATIC S7-1500 control system can also offer OPC UA methods for the clients via its integrated OPC UA server.

What are the requirements to connect HeidenHain PLC?

The Core Information Model version 1.04 described within this document is supported by HEIDENHAIN OPC UA NC Server starting with the following products and versions:

-

TNC7: NC software 817620-17 SP01, 817621-17 SP01, 817625-17 SP01

-

TNC 640: NC software 340590-17 SP01, 340591-17 SP01, 340595-17 SP01

-

TNC 620: NC software 817600-17 SP01, 817601-17 SP01, 817605-17 SP01

Model Version Product NC Software Version

1.00 TNC 640 34059x-10

1.01 TNC 640 34059x-11

TNC 620 81760x-08

1.02 TNC7 81762x-16

TNC 640 34059x-16

TNC 620 81760x-16

1.03 TNC 620 81760x-17

TNC7 81762x-17

TNC 640 34059x-17

1.04 TNC7 81762x-17 SP01

TNC 640 34059x-17 SP01

TNC 620 81760x-17 SP01

How to connect PLC via OPCUA?

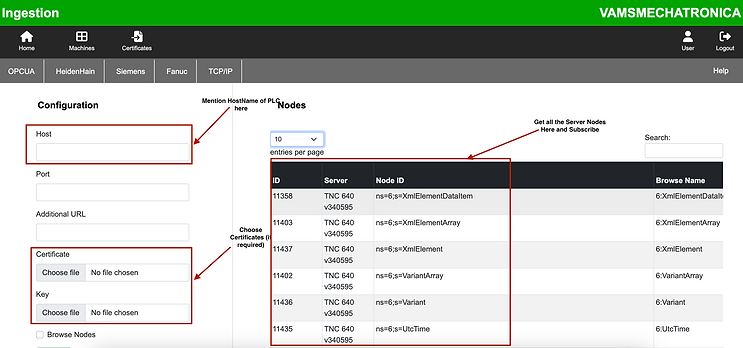

To connect any PLC or controller via opcua, you can use our application's Ingestion service.

Here, we need to pass PLC/CNC's hostname or IP address (if hostname is not available). We can also upload server certificate and key to have secured communications between the application.

Now click on submit to get all the nodes and displayed in grid with all details like Node ID, namespace etc. (please follow below image)

What is OPCUA?

OPC UA is an open and royalty-free set of standards designed as a universal communication protocol. While there are numerous communication solutions available, OPC UA has some key advantages:

-

A state-of-the-art security model

-

A fault-tolerant communication protocol

-

An information-modeling framework that allows application developers to represent their data in a way that makes sense to them

OPC UA has a broad scope which delivers for economies of scale for application developers. This means that a larger number of high-quality applications at a reasonable cost are available. When combined with semantic models such as the OPC UA NC Server Core Information Model, OPC UA makes it easier for end users to access data via generic commercial applications.

The OPC UA model is scalable from small devices to ERP systems. OPC UA Servers process information locally and then provide that data in a consistent format to any application requesting data – ERP, MES, PMS, Maintenance Systems, HMI, smartphone, or a standard browser,

Contact

There’s no better time like the present to get with the future! Leave your contact details with us so our team can get in touch and walk you through how vams' products is an investment you and your enterprise will be glad to have made.

#82, Phase V, Focal Point, Ludhiana

+91-161-4047267